Ventilation systems, Accessories & Adhesives

Ventilation systems

Ventilation is automated to suit the requirements of the stable.

Ventilation is automated to suit the requirements of the stable.

The system is assembled of polyurethane parts which offer many benefits compared to traditional materials:

- Good thermal insulating properties, no sweating, no damping, no freezing or rusting

- Self-cleaning due to smooth and hard surface

- Protected against aggressive gasses

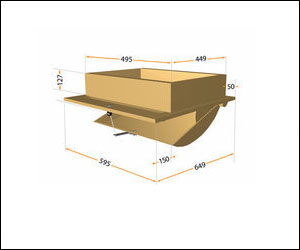

Suction cone with closing flaps

The polyurethane exhaust units are equipped with suction and blow cones.

The exhaust unit can also be equipped with adjustable closing flaps. In that case the fan is placed into the duct.

The correct shape of the exhaust unit is the key element in the true power and energy consumption in ventilation.

Exhaust units

- Low energy consumption

- Efficient flow

- Suitable for all buildings

Jet cap

The exhaust unit can be equipped with a jet cap that will direct the extraction flow efficiently upwards.

Exhaust units

Polyurethane exhaust ducts equipped with suction and blow cones.

The air flow counts for air inlets, m³/h

|

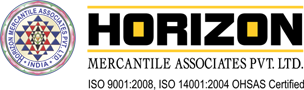

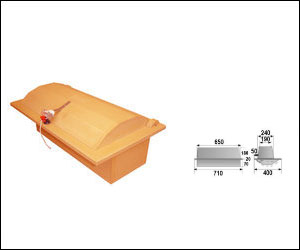

Ceiling inlet 535

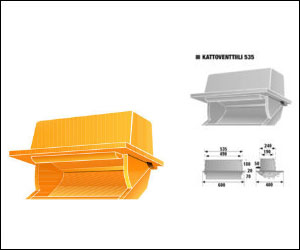

Ceiling inlet 535 Wall inlet 3000

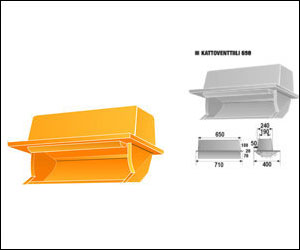

Wall inlet 3000 Ceiling inlet 650

Ceiling inlet 650

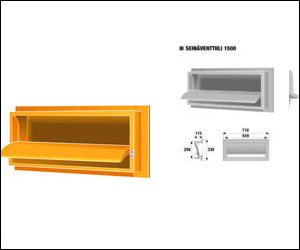

Wall inlet 1500

Wall inlet 1500 Ceiling inlet 650P2

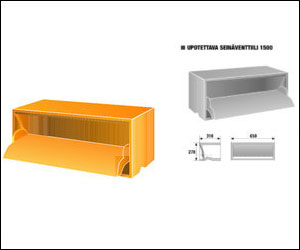

Ceiling inlet 650P2  Embedded wall inlet 1500

Embedded wall inlet 1500

Ceiling inlet 160P2

Ceiling inlet 160P2

Accessories & Adhesives

The application of adhesive agents to join multiple components is a common assembly process. From adhesive dispensing to

surface treatment to UV curing, ATS has the depth of experience to implement your bonding process successfully.

Bonding parts through adhesives is a practical assembly process, and the only joining option in some cases. The nature of the adhesive used is driven by characteristics such as the part substrate, the function of the adhesive (e.g. bonding, sealing), strength requirements, and environmental exposure.

Bonding parts through adhesives is a practical assembly process, and the only joining option in some cases. The nature of the adhesive used is driven by characteristics such as the part substrate, the function of the adhesive (e.g. bonding, sealing), strength requirements, and environmental exposure.

To be successful with adhesive in assembly operations, requires the following minimum attributes to be addressed through the design of the assembly automation system:

- * Surface treatment

- * Part fixturing

- * Adhesive application

- * Curing

SURFACE TREATMENT

Clean and debris free surfaces represent a baseline requirement for adhesive bonding applications. In some cases, however, special surface treatments such as corona are required to enhance the affinity of the bonding surfaces. ATS is experienced in delivering assembly systems that incorporate cleaning, buffing, and surface treatment to meet the bonding specifications.

PART FIXTURING

Holding and maintaining part orientation as well as relative part positioning during both adhesive application and curing is crucial to a successful bond. ATS carefully designs part fixtures to take into account all aspects of the adhesive specification to deliver the desired bonding result.

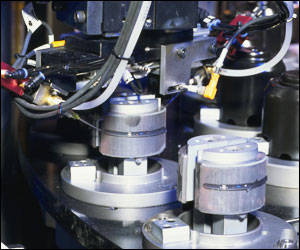

ADHESIVE APPLICATION

Delivering the adhesive agent to the target surfaces in the right volume and position is another key ingredient of bonding success. In most cases, some form of automated motion profile is required to deliver the adhesive on circumferential surfaces, linear surfaces, or other pathways.

ATS has a vast knowledge base and experience with both adhesive dispensers (including drawing adhesives from bulk storage) and delivering the required dispensing motion, whether using robotics, servo motion, linear actuators, or other articulating automation devices.

CURING

All adhesives have some form of curing requirement. This can range from supplying straight curing time (and delivering this through part storage methodologies such as curing conveyor towers), or the use of curing catalysts such as the application of UV light. ATS pays careful attention to the curing specification of the adhesive and implements automation solutions that meet the various customer constraints (including floor space limitations).